Written By: Pharmacally Medical News Desk

Astellas Pharma Inc. has received a key regulatory acknowledgment from the U.S. Food and Drug Administration (FDA) by securing an Advanced Manufacturing Technology (AMT) designation for its Maholo Robotic Cell Culture Automation System, marking a pivotal step in automating and improving cell therapy production.

The FDA’s AMT program is designed to promote the adoption of new manufacturing methods that improve the quality and reliability of drug production. Under this program, technologies that significantly enhance manufacturing while maintaining or improving product quality can earn a designation that helps streamline discussions with the agency and align regulatory expectations early in development. These designations are granted for specific contexts of use and can benefit companies planning to use the technology in regulated applications.

What the AMT Designation Means

The Advanced Manufacturing Technology designation signals that the FDA recognizes Maholo’s potential to improve the consistency and robustness of cell culture and cell therapy manufacturing. In practice, technologies with AMT designation can engage earlier and more frequently with FDA review teams, receive assignment of designated points of contact, and benefit from structured interactions that clarify regulatory expectations. This is especially useful for complex biologics and cell therapy manufacturing, where high precision and reproducibility are critical.

About the Maholo Robotic System

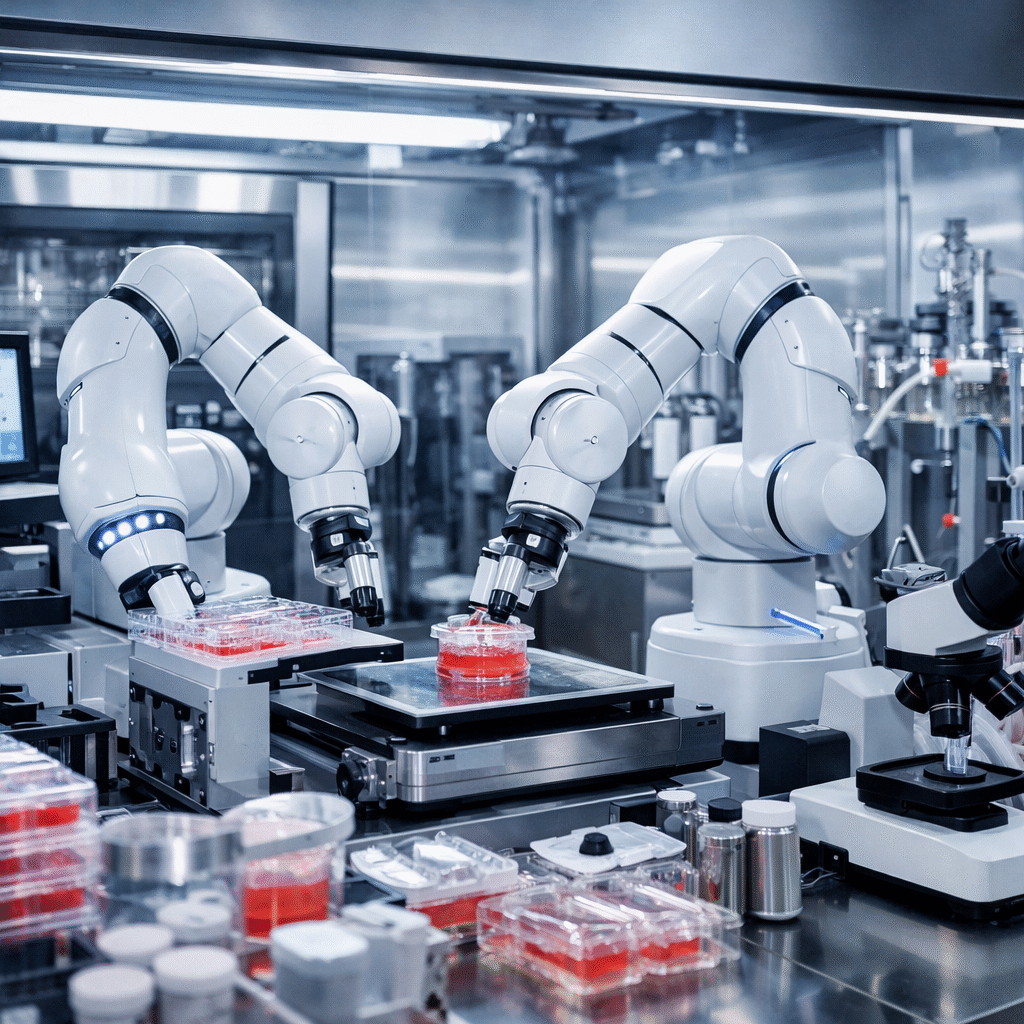

Maholo is a dual-arm robotic platform developed to automate laboratory processes that are traditionally labor-intensive and variable. By integrating robotics with digital control and artificial intelligence, Maholo can standardize delicate cell culture tasks, support high-throughput workflows, and reduce variability caused by manual handling.

Astellas and YASKAWA Electric Corporation, through their strategic collaboration and joint venture efforts, have focused on using Maholo to create a digitized cell therapy manufacturing platform. This platform is intended to improve precision and reproducibility, enable rapid transfer of manufacturing processes across facilities, and help academic and early-stage partners scale investigational products under good manufacturing practice conditions.

Rao V. Mantri, Ph.D., M.B.A., Chief Manufacturing Officer, Astellas, highlighted that cell therapy manufacturing is complex and central to product quality. He described the FDA’s AMT designation for Maholo as a major milestone that strengthens Astellas’ manufacturing capabilities and supports its goal of setting new standards for quality, scalability, and speed in cell therapy development.

Hideto Yamaguchi, Ph.D., President & CEO, Cellafa Bioscience, emphasized that Cellafa aims to build an end-to-end cell therapy manufacturing platform, from process development to GMP production. He noted that the AMT designation enables broader use of Maholo, helping accelerate development and supporting collaboration with academia and startups to advance cell therapy innovation.

References

Astellas Receives Advanced Manufacturing Technology Designation by U.S. FDA for Maholo Robotic Cell Culture Automation System, 18 December 2025, Astellas, https://newsroom.astellas.com/2025-12-18-astellas-receives-advanced-manufacturing-technology-designation-by-u-s-fda-for-maholo-robotic-cell-culture-automation-system